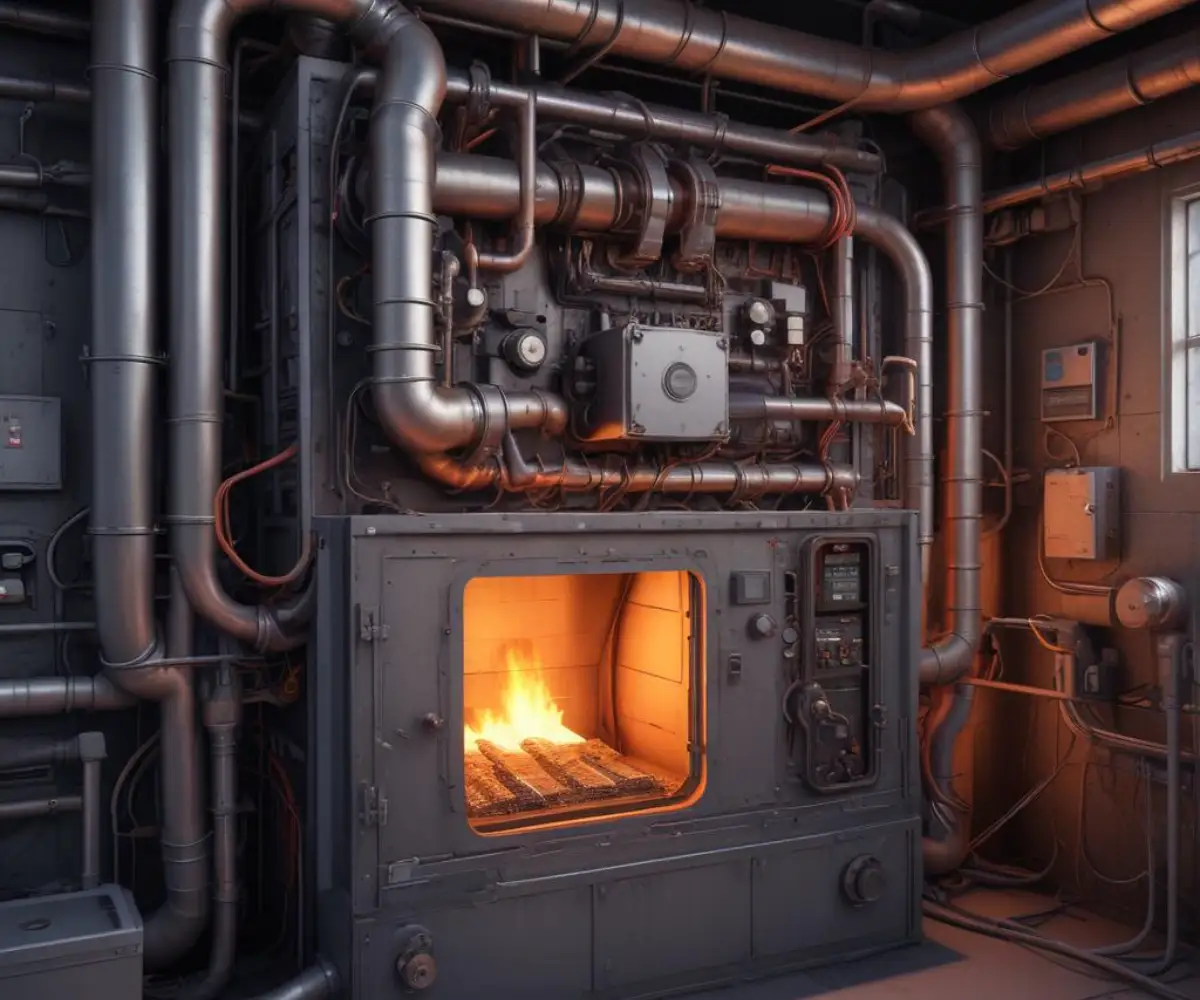

It’s a baffling and surprisingly common scenario: your furnace refuses to work, but the moment you remove the access panel, it roars to life. You’re left scratching your head, wondering if your heating system has suddenly developed a strange case of stage fright. While it might seem like a minor quirk, a furnace that only operates with its cover off is a significant red flag pointing to underlying safety and operational issues that demand immediate attention.

Ignoring this symptom is not an option. Running your furnace without its cover is not a long-term solution; in fact, it’s a dangerous gamble that can compromise your home’s air quality and safety. This guide will walk you through the surprising reasons behind this peculiar problem and provide actionable steps to diagnose and resolve it safely and effectively.

Why Does My Furnace Run Only When the Panel Is Off?

The core of this issue often lies with one of several critical safety components within your furnace. These parts are designed to shut the system down when unsafe conditions are detected. When you remove the cover, you inadvertently change the environment inside the furnace, which can temporarily mask the real problem.

Think of it like this: the furnace cover creates a sealed environment essential for proper airflow and pressure. Removing it introduces a flood of ambient air, altering the delicate balance the system needs to function correctly. This can trick sensors into thinking a problem has been resolved, when in reality, it’s just been temporarily bypassed.

The Usual Suspects: Key Components to Investigate

When your furnace exhibits this strange behavior, the investigation should start with a few key safety and operational parts. These components are highly sensitive to changes in air pressure and temperature, which is why removing the cover has such a dramatic effect on their function. Understanding their roles is the first step toward a correct diagnosis.

From pressure switches that monitor venting to rollout switches that detect dangerous flame behavior, each part plays a vital role in the safe operation of your furnace. A failure in any one of these can lead to the exact problem you’re experiencing. Let’s break down the most common culprits and what their failure means for your system.

The Pressure Switch: A Critical Airflow Guardian

The pressure switch is a safety device that ensures your furnace’s venting system is working correctly. It detects the negative pressure created by the inducer motor, which is responsible for pushing harmful exhaust gases (like carbon monoxide) safely out of your home. If the vent pipe is blocked by a bird’s nest, snow, or other debris, the inducer motor can’t create the necessary draft.

When you remove the furnace cover, the system can suddenly pull enough air from the surrounding room to satisfy the pressure switch, allowing the furnace to start. However, this doesn’t fix the blocked vent, meaning dangerous flue gases could still be lingering. It’s crucial to inspect and clear any blockages in the intake and exhaust pipes leading outside your home.

Flame Rollout Switch: Your First Line of Defense Against Fire

Another critical safety device is the flame rollout switch. This component is designed to detect flames that are “rolling out” of the combustion chamber, which is a sign of a serious problem like a cracked or blocked heat exchanger. If this switch trips, it will shut down the furnace to prevent a potential fire hazard. These switches are typically manual reset, meaning they need to be physically pushed to be reset.

Removing the cover can alter the airflow in a way that temporarily prevents flame rollout, allowing the furnace to operate. However, if the rollout switch has tripped, it’s a sign of a dangerous condition that needs to be addressed by a professional. Do not repeatedly reset a rollout switch without identifying and fixing the root cause.

Step-by-Step Troubleshooting Guide

Before calling for professional help, there are several diagnostic steps you can take to pinpoint the issue. This process requires caution and a basic understanding of your furnace’s components. Always remember to turn off the power to your furnace at the circuit breaker before beginning any inspection.

This systematic approach will help you rule out simple issues and gather valuable information if you do need to contact an HVAC technician. By carefully observing your furnace’s behavior and inspecting key components, you can often get to the bottom of the problem yourself.

Step 1: The Blower Door Switch

The most straightforward cause is the blower door switch (or interlock). This is a simple safety switch that cuts power to the entire unit when the access panel is removed. Its purpose is to protect you from moving parts and live electrical components.

Sometimes, this switch can become faulty or misaligned. When you put the cover back on, it might not be depressing the switch plunger properly, leading to a loss of power. Check that the switch is being fully engaged when the door is closed and that the switch itself is functioning correctly.

Step 2: Inspecting for Airflow Restrictions

Restricted airflow is a primary cause of many furnace problems, including this one. A severely clogged air filter can starve the system of the air it needs, leading to overheating and tripping the high-limit switch. When you remove the cover, the system can suddenly draw in enough air to cool down and resume operation.

Start by checking your furnace filter. If it’s dirty, replace it. Also, ensure that all supply and return vents throughout your home are open and unobstructed by furniture or rugs. In some cases, the issue could be more severe, like an undersized or collapsed ductwork system, which will require professional assessment.

Step 3: Checking the Condensate Drain Line

For high-efficiency condensing furnaces, a clogged condensate drain line can cause water to back up into the system. This can trip a pressure switch or even short out electrical components. The drain line can become blocked with sludge or algae over time.

Inspect the clear plastic tubing that leads away from your furnace. If you see standing water or signs of a blockage, you’ll need to clear the line. This can often be done by disconnecting the tube and using a shop vacuum to suck out the clog.

When to Call a Professional

While some troubleshooting can be done by a homeowner, there are definite signs that it’s time to call in a licensed HVAC professional. Electrical testing, handling gas components, and diagnosing complex control board issues are tasks best left to those with the proper training and tools. Your safety is the top priority.

If you’ve gone through the basic troubleshooting steps and the problem persists, or if you encounter any of the more serious issues described below, do not hesitate to seek expert help. Attempting advanced repairs without the necessary expertise can lead to further damage to your furnace or create a hazardous situation in your home.

Signs You Need an Expert’s Help

- Repeatedly Tripping Rollout Switches: This indicates a potentially cracked heat exchanger, which can leak carbon monoxide into your home. This is an emergency situation.

- You Suspect a Bad Pressure Switch: While you can check for blockages, testing the switch itself requires a multimeter and knowledge of electrical circuits.

- Error Codes on the Control Board: If your furnace’s control board is flashing a diagnostic code, a technician can interpret it and quickly diagnose the problem. This is especially true for complex issues like those seen in a Trane XV80 red light flashing scenario.

- You Smell Gas: If you ever smell gas near your furnace, leave the house immediately and call your gas company from a safe distance. Do not attempt any repairs.

A professional technician has the diagnostic equipment, such as a manometer to test pressure switches accurately, and the experience to safely and correctly repair your system. Investing in a professional diagnosis can save you from costly and dangerous mistakes.

| Potential Cause | Common Symptoms | DIY Fix or Professional? |

|---|---|---|

| Faulty Door Switch | Furnace has no power when cover is on; works when switch is manually depressed. | DIY (If comfortable with basic electrical safety) |

| Clogged Air Filter | Furnace overheats and shuts down; may see a high-limit switch error code. | DIY (Replace filter) |

| Blocked Vent Pipe | Furnace fails to ignite; pressure switch error code is common. | DIY (Inspect and clear external pipe openings) |

| Tripped Flame Rollout Switch | Furnace won’t ignite; switch needs manual reset. This is a major safety concern. | Professional Only |

| Clogged Condensate Line | Water leaking around the furnace; pressure switch error code. | DIY (Clear the drain line) |

| Cracked Heat Exchanger | Rollout switch tripping; strange smells; symptoms of carbon monoxide exposure. | Professional Only (Emergency) |

The Dangers of Running a Furnace Without a Cover

It can be tempting to leave the cover off as a temporary “fix,” but doing so introduces serious risks. The cover is not just a cosmetic panel; it is an integral part of your furnace’s safety and operational design. Running the system without it is a recipe for disaster.

First and foremost is the risk of carbon monoxide (CO) poisoning. The cover helps maintain a sealed combustion system, ensuring that all flue gases are properly vented outside. Without it, negative air pressure created by the blower can pull toxic gases back into your home, a dangerous phenomenon known as backdrafting.

Additionally, you risk damaging the furnace itself. The blower will pull in unfiltered, dusty air from your basement or utility closet, clogging internal components and reducing efficiency. Lastly, there is a significant risk of fire or electrical shock from the exposed flames and wiring. Never operate your furnace without all access panels securely in place.

A Note on Combustion Air

Modern high-efficiency furnaces often have a dedicated PVC pipe to draw in fresh air from the outside for combustion. However, older or standard-efficiency models may draw combustion air from the room they are in. If this room is sealed too tightly (a common result of home energy efficiency upgrades), the furnace can be starved for air.

This air starvation can lead to incomplete combustion, sooting, and the production of carbon monoxide. In some cases, removing the cover provides the air the furnace needs, masking the underlying problem of inadequate ventilation. Ensure your furnace room has sufficient openings or louvers to provide the necessary combustion air as specified by your furnace manufacturer and local building codes.

Preventative Maintenance: The Key to Reliability

The best way to avoid bizarre furnace behavior and costly repairs is through regular, preventative maintenance. An annual tune-up by a qualified HVAC technician can catch potential problems before they escalate into a no-heat emergency. This is not just about reliability; it’s about safety.

During a maintenance visit, a technician will clean and inspect all critical components, including the burner assembly, flame sensor, heat exchanger, and all the safety switches discussed here. They will test gas pressure, check for proper venting, and ensure the system is operating safely and efficiently. For specialized systems, like those needing Carlin gas conversion burner troubleshooting, expert maintenance is even more critical.

Between professional visits, your primary responsibility is to check and change your air filter regularly. A clean filter is the single most important thing you can do to ensure proper airflow, maintain efficiency, and extend the life of your furnace. Mark your calendar and make it a habit; your heating system will thank you for it.