Installing a hoist in your garage can be a game-changer, opening up new possibilities for vehicle maintenance, heavy lifting, and clever storage solutions. But before you mount that powerful piece of equipment, there is a critical and often overlooked danger lurking right above your head. Your garage ceiling was almost certainly not designed to handle the immense, concentrated force of a hoist, and skipping the reinforcement step can lead to catastrophic failure.

A standard garage ceiling is built to support a distributed, static load—primarily the weight of the drywall itself. A hoist introduces a completely different kind of stress: a heavy, concentrated, and dynamic load. This distinction is the key to understanding why reinforcement isn’t just a suggestion; it’s an absolute necessity for safety and structural integrity.

The Hidden Dangers: Why Your Ceiling Is Not Hoist-Ready

The structural members in your ceiling, known as joists or trusses, are engineered to work as a system. They distribute weight evenly across the walls of your garage. When you hang a hoist from a single point, you bypass this system entirely, placing a massive strain on one or two joists that were never meant to bear such a burden alone.

This creates several serious risks, including ceiling collapse, damage to your home’s framing, and severe injury from falling equipment or lifted items. The problem is magnified by dynamic forces; the initial jerk of lifting an object and the sudden stop can multiply the stress on the ceiling far beyond the object’s actual weight. This concept, known as shock loading, is what turns a 500-pound engine block into a 1000-pound force for a split second, potentially causing an immediate structural failure.

Understanding Your Garage’s Structure: Joists vs. Trusses

Before any work begins, you must identify what kind of structure you have. Go into your attic or crawlspace and look at the framing above the garage. You will see one of two designs:

Ceiling Joists: These are simple, solid wood beams running parallel to each other from one wall to the other. They are typically made of 2×6, 2×8, or larger dimensional lumber. Garages with a flat ceiling and usable attic space above are often built with joists.

Trusses: These are engineered, prefabricated structures composed of smaller pieces of wood (like 2x4s) connected in a web-like pattern with metal plates. You should never cut, drill, or modify a truss without consulting a structural engineer. The bottom chord of a truss is under extreme tension, and altering it can compromise the entire roof structure of your home.

Calculating Your Total Load Requirement

To reinforce your ceiling correctly, you must first calculate the maximum potential load. This isn’t just the weight of what you plan to lift. The formula is a combination of the hoist’s weight and its maximum rated capacity, plus a crucial safety factor.

(Hoist Weight + Max Lifting Capacity) x Safety Factor = Total Load Demand

For example, if you have a 50 lb hoist with a 1,000 lb capacity, your base load is 1,050 lbs. A conservative safety factor of at least 2x is recommended, meaning your reinforcement should be designed to handle a minimum of 2,100 lbs. This accounts for shock loading and provides a buffer for safety.

The Ultimate Guide to Reinforcing Your Garage Ceiling

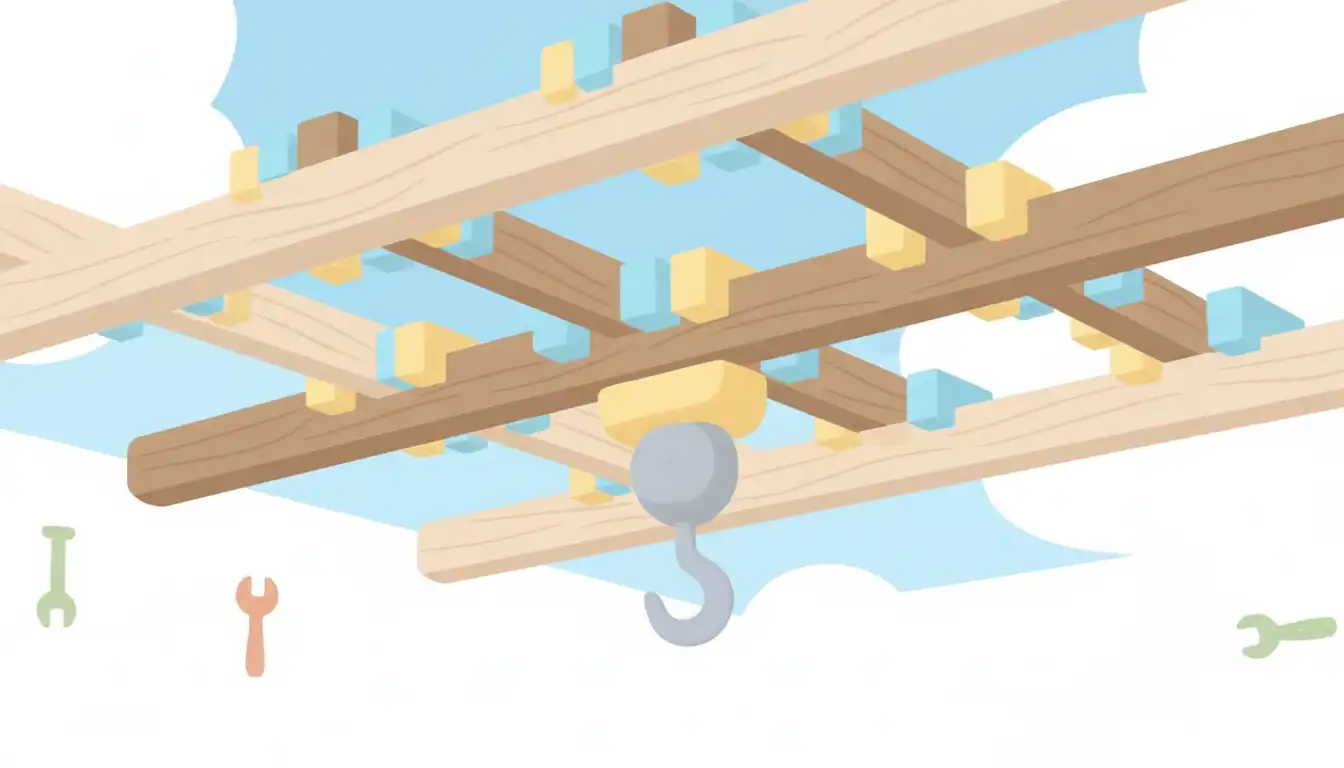

The fundamental principle of reinforcing a garage ceiling for a hoist is load distribution. Your goal is to take the concentrated point load from the hoist and spread it across multiple joists, allowing them to work together as a system. Here are the most effective methods to achieve this.

Method 1: The Cross-Beam Spreader (Most Common & Effective)

This is the gold standard for most DIY hoist installations. The method involves laying a substantial beam, such as a 4×6 or a doubled-up pair of 2x8s, perpendicular across the tops of several ceiling joists in the attic. The hoist is then mounted to this cross-beam, effectively spreading the load over three, four, or even five joists.

Step-by-Step Installation:

- Locate and Mark Joists: Use a stud finder from below or measure from the attic to identify the joists you will span. Aim to span at least three, but preferably four or more, joists.

- Measure and Cut the Beam: Measure the distance needed for your cross-beam to lie flat across the top of your chosen joists. Cut your lumber (e.g., a 4×6) to length.

- Position the Beam: Lay the beam in the attic across the joists in the precise location where you intend to mount the hoist.

- Secure the Beam: Fasten the cross-beam to each joist it crosses using structural screws or lag bolts. Do not use drywall or deck screws, as they lack the shear strength required. Pre-drilling pilot holes is recommended to prevent the wood from splitting.

- Mount the Hoist: Drill through the cross-beam and mount your hoist using high-grade bolts, washers, and locking nuts.

Method 2: Sistering the Joists

If your existing joists are undersized (e.g., 2x4s) or you are planning to lift very heavy loads, “sistering” provides additional strength directly to the primary joists. This involves adding a new joist of the same size directly alongside one or more of the existing joists that will bear the load.

To do this, apply a generous amount of construction adhesive to the side of the new joist and press it firmly against the existing joist. Secure it with a staggered pattern of structural screws or nails every 8-12 inches. Sistering is often used in combination with the cross-beam method for maximum support.

Method 3: Adding Blocking

Under a heavy load, joists have a tendency to twist or roll over. To prevent this, install “blocking.” Blocking consists of short pieces of lumber of the same size as your joists, installed snugly and perpendicularly between them. This creates a more rigid, box-like structure that resists torsional forces. Install blocking on both sides of the joist where the hoist is mounted, as well as between the adjacent joists that are supporting the cross-beam.

Advanced Considerations and When to Call a Professional

Not every garage is a simple, open-joist structure. Finished ceilings with drywall require careful cutting to access the framing, and the presence of trusses changes the entire approach. Before you begin any structural work, it’s wise to do a full inspection of your garage, from the floor up. Issues on the slab, like wondering why grout looks wet in spots, could indicate underlying moisture problems that should be addressed first.

While the reinforcement methods described are suitable for many standard garages, there are clear signs that you should stop and consult a licensed structural engineer. If your planned load exceeds 1,000 pounds, if your garage is built with trusses, or if you notice any pre-existing sagging or damage to the ceiling, professional guidance is essential. The cost of a consultation is minor compared to the cost of a structural failure.

Choosing the Right Hardware Is Critical

The strength of your reinforcement is only as good as the fasteners holding it together. Using the wrong hardware is a common and dangerous mistake. Just as proper footings are critical for stability in outdoor projects, like when using sonotubes for fence posts, the support for your hoist must be anchored with appropriate, load-rated hardware.

The table below compares common fasteners and their appropriate uses for this project.

| Fastener Type | Best Use Case | Pros | Cons |

|---|---|---|---|

| Lag Bolts (Lag Screws) | Securing a cross-beam to joists. | Strong holding power; widely available. | Requires pre-drilling; can split wood if not careful. |

| Through Bolts (Carriage or Hex) | Mounting the hoist through the cross-beam. | Extremely strong clamping force; very secure. | Requires access to both sides for nut and washer. |

| Structural Screws | Securing cross-beams and sistering joists. | High shear strength; often no pre-drilling needed. | More expensive than lag bolts. |

| Deck/Drywall Screws | DO NOT USE for structural support. | Inexpensive and common. | Brittle and have very low shear strength; will snap under load. |

Common and Dangerous Mistakes to Avoid at All Costs

Even with a solid plan, simple errors can compromise the safety of your hoist installation. Be mindful of these common pitfalls that can lead to failure.

Mistake #1: Mounting to a Single Joist

This is the most frequent and dangerous error. A single joist cannot handle the concentrated dynamic load of a hoist. Always distribute the load across multiple joists with a cross-beam.

Mistake #2: Underestimating the Total Load

Forgetting to include the weight of the hoist itself or failing to account for the dynamic forces of lifting can lead to under-building your support system. Always use a safety factor in your calculations.

Mistake #3: Altering Trusses

Cutting, drilling, or removing any part of a truss system can have a domino effect, weakening the entire roof structure. While these instructions are geared towards standard stick-built garages, the principles of load distribution are even more critical in other structures. If you’re working on a different type of building, such as learning how to enclose a pole barn, the framing will be entirely different and require a unique engineering approach.

Mistake #4: Using Inadequate Fasteners

Never use deck screws, drywall screws, or common nails for structural connections in this project. Their shear strength is far too low. Always use properly rated structural screws, lag bolts, or through bolts to ensure a secure and lasting installation that can handle the forces involved.